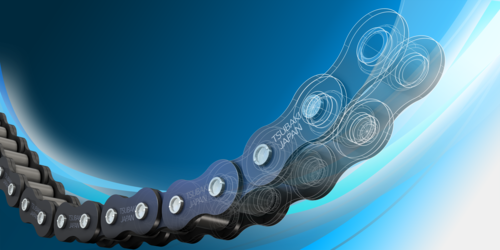

Roller chain upgrade reduces costs for pizza making operation

Roller chains used to drive food packaging machines have to ensure stable motion. With produce destined for demanding supermarkets, conveyors driven by roller chains must maintain the quality of packaged produce, as well as high throughput. A French food manufacturer turned to Tsubaki to provide a roller chain that would not just reduce maintenance requirements and replacement costs, but also contribute to increased productivity.