For standard situations, Tsubaki can provide you with two outstanding roller

chains:

the GT4 Winner and the ANSI G8

Since 1917 Tsubakimoto Chain Company has maintained a line-up

of cutting-edge chain products with exceptional quality and performance that

help end-users meet their power transmission and conveying requirements. Tsubaki

is proud to introduce the 4th generation, enhanced BS/DIN European premium chain.

The product is available in chain sizes from RF06B up to RS48B*. Simplex, duplex

and triplex executions are at your disposal.

* RF06B curled

bush; RS56B/RS72B on request

Advantages

Tsubaki GT4 Winner is enhanced with the following

advantages:

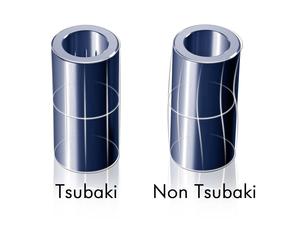

Lube Groove (LG) Bush

Tsubaki Lube Groove (LG) seamless

bushes are precision components and perfectly cylindrical. Our special lube

grooves hold oil at the point of contact, where the chain needs it most, providing

an internal reservoir for lubricant. The result is a chain that lasts longer

with lower maintenance costs over the lifetime of the chain.

Seamless Bush: Perfectly Cylindrical

The new Tsubaki

BS/DIN series chain has a seamless bush with a very precise cylindrical profile

and surface finishing resulting in better surface contact between the pin and

bush, and improved lubricant retention.

Ring Coin: Increased Transmission Capacity

The Ring Coined

connecting link allows the chain to be specified up to its full kW rating. The

precision and strength achieved on these components is far beyond that of competitor's

offerings. The typical standard slip-fit connecting link is usually much weaker

than the other links. Tsubaki's Ring Coin technology has overcome that.

Easy dis-assembly

With Tsubaki's design of rivet head,

the chain is easily dis-assembled with an additional benefit being that in the

event of the chain being overloaded, the markings on the rivet head will identify

pin rotation.

CO2 Reduction

Tsubaki takes its environmental

responsibility very seriously in its state-of-the-art production facilities.

The new BS/DIN series chain contributes significantly to reducing CO2

emissions due to the strongly extended replacement frequency.

Constant Quality Level

In pursuit of outstanding quality,

every Tsubaki chain is made of a special steel alloy, the specification of which

has been developed by the Tsubaki Engineering Department, for selected steel

mills to work with. Besides that, Tsubaki produces the GT4 Winner under highly

controlled conditions in its advanced heat treatment facilities. This, in combination

with the Tsubaki fatigue strength confirmation tests, ensures that our customers

can always rely on a constant level of Tsubaki quality.

Availability

Supplied in a new high quality box design

for the European market, GT4 Winner is available in sizes 06B to 48B as standard,

larger sizes are available on request. Stock of the new GT4 Winner chain will

be held by TSUBAKI throughout Europe and by many leading distribution partners,

making it available for next-day delivery in most areas.

For more detailed information about the BS/DIN GT4 Winner chain click here

Tsubaki's 8th model upgrade, celebrating 100 years of quality. Pursuing the ultimate in quality, Tsubaki has created the world's highest standard of roller chain.

Technical Evolution

All ANSI Chains Are Not Created Equal

ANSI defines minimum

threshold standards: acceptable, but they won't improve your bottom line. Tsubaki

ANSI G8 Chains set the bar higher with design innovations that deliver solid

results!

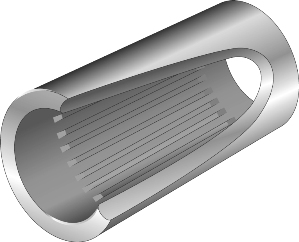

Solid Lube Groove Bush - Our Latest Innovation

Unlike

curled bush, Tsubaki SOLID Lube Groove Bush does not have a split. This means

that oil cannot leak from the bearing area as a result of that type of manufacturing

process. Additional to that innovation Tsubaki developed a unique process to

add grooves to the inner surface of the solid bush. This lube groove process

ensures longer and better lubrication which results in an extended chain life.

The Lube Groove Bush is available in ANSI sizes RS80 through RS140, perfectly

sized for the most demanding applications.

Advantages

Tsubaki has enhanced the ANSI G8 with the

following advantages:

Save Operating Costs and Reduce Downtime

Normally, ANSI

chains are removed or replaced due to elongation caused by wear in the pin-bush

joint. The patented Lube Groove retains lubricant right where it's needed: in

the pin-bush joint. In many applications you'll notice a significant difference

in maintenance, operating, and replacement costs due to the increased reliability

of the ANSI G8 chains.

Increased kW Rating

Transmission capacity has been increased

by applying the patented Tsubaki Ring Coining process on the connecting link

plate.

For easy assembling the pin and link plate of a connecting link are slip fit. In general, this type of connecting link has a 20% lower fatigue strength than the chain itself. However, Tsubaki developed a special process to eliminate that loss of Fatigue Strength and still satisfy the customers demand for easy assembly: the patented Ring Coining process. By applying the patented Ring Coining process, Tsubaki generates a cold deformation around the pin hole of the connecting link plate. This results in residual stress around the pin hole and thereby adds strength. By using this process transmission capacity is increased to 100% of that of the base chain.

Constant Quality Level

In pursuit of outstanding quality,

every Tsubaki chain is made of a special steel alloy developed by the Tsubaki

Engineering Department.

Besides that, Tsubaki produces the ANSI G8 under

highly controlled conditions in its advanced heat treatment facilities. This,

in combination with the Tsubaki fatigue strength confirmation tests, ensures

that our customers can always rely on a constant level of Tsubaki quality.

For more detailed information about the ANSI G8 chain click here