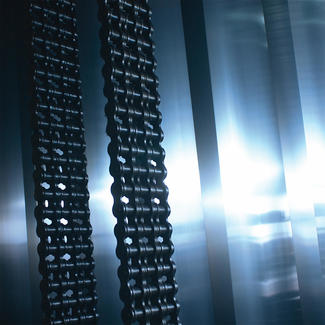

Following the links of the total cost of life for chain

Specifying higher quality mechanical power transmission products usually comes with a price premium. Of course, when specified correctly, this premium can be more than recouped by their longer working life and lower maintenance requirements. Plant engineers and machine designers are advised to look at the 'total cost of ownership' rather than the purchase price when buying components such as transmission chain.

Peter de Blok, Sales Manager EMEA for Tsubakimoto Europe B.V., says a few minutes lost production due to unexpected machine stoppage is often far more expensive than the extra cost of quality parts.

The developed nations of the western world currently are trying to break the cycle of consumption and disposal that has driven markets and economies for the last 50 or more years, but which are so detrimental to resource and ecology management. Like all ingrained habits this cycle is hard overcome, even though we know it is ultimately destructive to the planet.

This hasn't always been the prevailing consumer attitude. Prior to mass-production techniques, nearly everything was built to last and over-engineering was the order of the day. However, this made engineering components expensive and heavy; therefore, inefficient in dynamic mechanisms. Clearly, then, there is a balance point where parts are optimally designed for a long, trouble-free working life without impacting on performance efficiency.

This optimised design concept leads to the idea of a calculable 'total cost of ownership' (TCO) or full life cost, which itself can be optimised for maximum effect.

Throughout the latter half of the 20th Century there has been a conflict in the plant and machinery engineering community. Plant operators want reliable, low maintenance machinery that runs and runs (i.e. quality parts), while OEMs want to build machines that they are competitive in the market (i.e. budget parts).

But things are changing: increasingly, operators are asking for quality parts in OEM machines and justifying their requests by citing TCO.

In its simplest form, TCO is the purchase price plus the costs related to maintenance procedures during the working lifetime of the product: in some cases, it is appropriate to also add a cost for the installation procedure. In real life scenarios manufacturing environments will also have to account for the production lost during the time taken to carry out maintenance. This latter element can have a large effect on the bottom line when a quality part reduces the occurrence of maintenance downtime.

When considering chain, quality is designed in by using the best materials; manufacturing parts to exacting dimensional tolerances; heat treating links and pins with precision accuracy; and assembling them into finished chain with supreme care.

Unfortunately, quality chain does not look that different from budget chain, so engineers must make a point of learning which are the quality brands and which are not. Tsubaki is recognised the world over as the leading manufacturer of industrial chain. It maintains this position through constant R&D and always-improving its manufacturing. Further, it offers excellent support services for both MRO specialists and end-users and strives to form strong, supportive relationships with customers and users alike so that its expertise is available to all.

Tsubaki offers chain in a wide range of sizes and formats so that it meets the needs of the widest possible user base.TCO has always been a prime concern for Tsubaki and its engineers identify unexpected downtime, early failure and frequent replacement as major contributors to uncertainties in TCO calculation. These can all be reduced by the use of quality chain which leads to less likelihood of lost production.

With over 100 years of company history, Tsubaki has honed it philosophy of 'quality counts' over many individual experiences. For example, a confectionary producer was experiencing frequent stoppages due to chain failure, so they asked Tsubaki to replace their chain drives with a quality alternative, in the first year of operation this achieved savings of over €148.000. Elsewhere, Tsubaki has helped a steel mill save over €114.000, while a car manufacturer is almost €263.000 better off thanks to upgrades in chain quality.

To sum up, there are some simple rules that will go a long way to managing TCO. Perhaps the most important one is to buy quality chain, either directly from the manufacturer or through a reputable third party - cheap chain is nearly always a false economy. It is also important to select the most appropriate size and style of chain - and don't be afraid to ask for advice from a chain expert. It is always worth considering a lube-free option such as Tsubaki's Lambda chain which requires less maintenance and may save more money as it reduces cleaning needs caused by manual relubrication processes.

Next, at installation and re-installation, make sure to check the tension, alignment, and if appropriate load sharing over multiple chains; in fact, it is a good idea to double check it or to get a colleague to check your work. And finally, don't immediately comply with the accounts department if they suggest buying cheap chain; instead take the opportunity to explain how TCO relates to chain.

Society at large is now addressing the false economies of disposable consumer products and as such is following those engineers who manage TCO through the use of quality chain