Home » News » Industry Applications » Clutch replacement brings increased reliability for bucket elevators

Clutch replacement brings increased reliability for bucket elevators

When a bucket elevator manufacturer was experiencing reliability problems with its backstop clutches, resulting in intensive maintenance and frequent replacement, it turned to Tsubaki for a solution.

Replacing the trapped roller design with a sprag clutch delivered higher torque capacity and longer life.

Bucket elevators provide a simple but effective mechanism of hauling and lifting flowable or semi-flowable bulk materials, including grain, fertiliser, foods, wastes and minerals, often into storage silos.

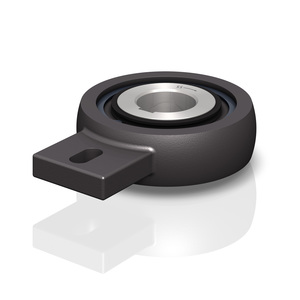

Designed specifically for use on the low speed shaft of inclined and bucket conveyors, the BSEU backstop cam clutch provides the safest reverse rotation prevention qualities available.

Designed specifically for use on the low speed shaft of inclined and bucket conveyors, the BSEU backstop cam clutch provides the safest reverse rotation prevention qualities available.

Their versatility means they can be easily tailored for use with challenging products, including fragile or abrasive materials. But in all cases, safety is a prime concern, and the main shaft that drives the belt will always be fitted with a backstop clutch. This enables driving of the bucket in one direction, but ensures there is no backwards slippage in the event of a drive problem.

The inherent weight of the bulk material, combined with their often abrasive nature and the fact that the bucket elevators are often operating outdoors and exposed to the weather, all combine to create a harsh operating environment. The high levels of torque, plus the inherent dust, debris, rain, sleet, snow and temperature extremes all take their toll on the drive train.

For one leading manufacturer of bucket elevators, the backstop clutch in particular was causing reliability problems. High running temperatures were leading to early failure of the product and while safety was never compromised, it was certainly leading to increased maintenance requirements and regular clutch replacements.

Looking for a solution, the company called in Tsubaki's engineers, who analysed the problem and recommended that the trapped roller backstop clutch be replaced by a Tsubaki BSEU sprag style alternative. Designed specifically for use on the low speed shaft of inclined and bucket conveyors, the BSEU backstop cam clutch provides the safest reverse rotation prevention qualities available.

Trapped roller clutches feature an inner race with ramps and individually sprung rollers. The rollers rotate during freewheeling in the drive direction, but in the reverse direction the rollers lock against the outer race and inner race ramps to ensure instantaneous backstopping. The sprag clutch provides an alternative design, where cam shaped sprags separate the inner and outer races. The angle of the sprags allows movement in the forward direction, but provides instant backstopping in the other.

The Tsubaki BSEU features an increased number of sprags, which enables greater torque transmission in relation to the clutch's size and weight when compared with a trapped roller clutch, resulting in extended fatigue life. Further, overheating when the motor is idling is lower, which helps maintain lubrication by means of grease instead of oil and so improves the clutch's wear life and ensures less maintenance.

A further feature of the BSEU is its sealing arrangement. V-ring seals are fitted as standard to offer the highest level of protection against dust. Even higher specification sealing is available for applications where protection is needed from the most extreme environmental conditions, such as fly ash, coal dust, splash water and many others.

Being dimensionally similar to other styles of backstop clutch, the BSEU offered the elevator manufacturer an easy upgrade path over its existing clutch. Fitted to the latest models of bucket elevators, the BSEU clutches are delivering safe operation, higher torque capacity, faster operating speeds, less maintenance and longer life.

You can download the Tsubaki Cam Clutch and Mechanical Components brochure here.